By some reason I thought since the begining of the overhauling that the gearbox was in a nice condition. Thus, I didn’t reviewed it. In fact, I didn’t even emptied the oil. During the overhauling of the SV13 the time arrived to check the gearbox. I switched the power on… and the gearbox made an intense rattling noise in some speeds 🤨.

Context

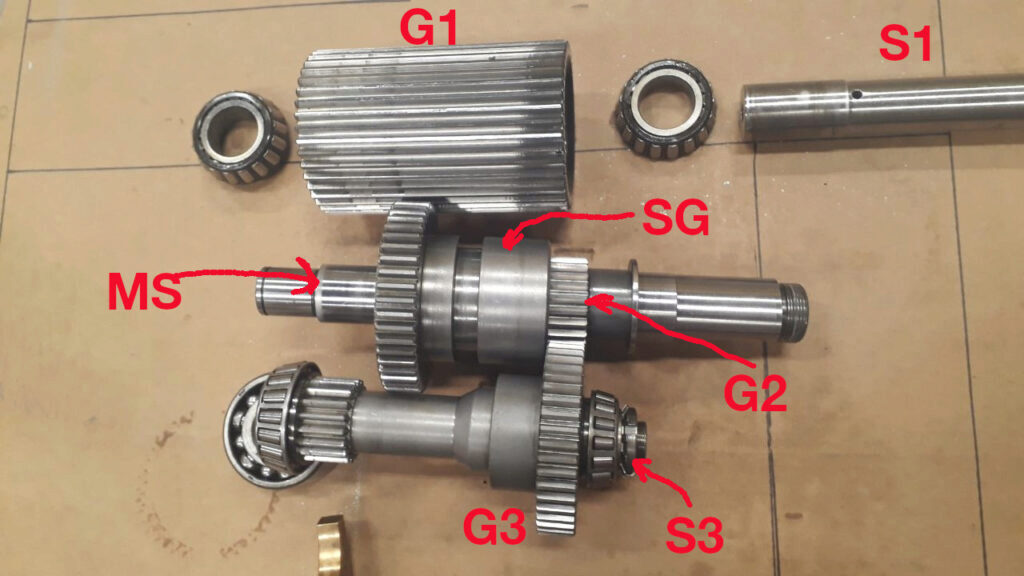

This is a picture of the gear train when the «direct speed» is selected:

In the picture, MS is the main shaft where the variable speed driver belt is attached (to the right of this shaft). Over the main shaft slides the assembly SG. The main shaft has a pinion G2 that is permanently engaged to gear S3. At the same time, G2 is acts as a dog clutch of the sliding gear SG: the right end of SG engages G2 and makes the main shaft and the sliding gear to turn together. This is the position shown in the picture. The gear SG is permanently engaged to G1, the long gear that transmits the power to the milling machine horizontal spindle.

You select the low speed by sliding SG to the left. Then SG engages to the pinion of S3 shaft. Next picture shows the gear train in the low speed position:

Additionally, there is a intermediate position of SG where it is engaged to no pinion and turns freely over main shaft. In this position, the long gear G1 is unconnected to the main shaft.

After emptying the oil and disassembling the gearbox the following facts were discovered:

The plain bronze bearing of the sliding gear SG was heavily worn: about 0.5 mm in the side of the gear and about 0.1 mm in the side of the dog clutch.

Bearings look nice enough. Maybe a bit of micro pitting. The big bearing supporting the main shaft pulley efforts may have a bit of play but nothing extremely important.

The gears do not have visible damage. Most of them looks like new. Indeed, the gear supporting the bearing play shows no signs of bad wearing.

It seems to me that the gearbox has not been never opened. However, the small cover plate has been opened for sure: I guess that the big bearing is not an original one.

The sliding gear assembly has a dog clutch that engages the pinion on the main shaft. This is really an internal gear that fits over the pinion. This part of the sliding appeared with some dents resulting from having been peened with a hammer. This really intrigued me as the gearbox seems never repaired. Do the guys at Schaublin use the hammer to adjust this part? Do they try to correct some out-of-round? Do they try to guarantee that the clutch slides in and out smoothly?

Plain bearing repair

I asked Schaublin for a spare of the sliding gear. They answered that they have no spares now although its not unusual to have some of them. The spare part includes the main shaft and the sliding gear all together. The price was high but I thought it is more or less appropriate. They kindly gave me the drawing of the bearing with its tolerances.

The drawing spicified the material as bronze «Duralit 110» which should be a specific foundry reference. I didn’t find a catalog of Duralite bronzes but indirectly, some docs found let me know that Duralit 110 is equivalent to Rg7 bronze.

I turned a new bearing according to the drawing. More in the tight side of the tolerance. Replaced the worn bearing and assembled again the gear train. Unfortunately, the clutch do not engaged smooth enough. This was the result of a better fitting of the bearing!! I worked it until it fits smoothly but with no play.

The next video shows some details of the turning job and, the following one, shows the smooth fitting of the clutch.

Gearbox with the new bearing rattles

After assembling again he gearbox I tested it under power. When assembling I reversed the long gear to take advantage of the best looking part of it. To my annoyance, the gears train shows a (rattling) sound under the direct speed, more audible when running at low rpm.

Why?

I began a set of tests to gain some insight into the reasons why the gearbox is making noise. I disassembled the gearbox again, replaced the big bearing and assembled the box without the idle shaft. I try to proceed by first understanding where the noise originated.

From this, is clear that the noise comes from meshing of the sliding gear and the long gear. However, the noise is only made when the direct speed is used. Thus it seems that there is nothing to do with the profile of the teeth being worn.

From the test I realised on the following fact. When the gearbox handle is in the neutral position (not engaged to low nor direct speed) the tight fit of the new bearing together with the oil shearing resistance makes the sliding gear to rotate at a good speed, driving the long gear and the toolholder. Surprisingly, in this position no noise is produced. From this observation I conduced the following test:

Run the gearbox without idle shaft in direct speed. Rattling is clear.

Run the gearbox in the last conditions but the handle is in the neutral position. There is no noise.

Run the gearbox in the last conditions. Begin with the handle in a direct position but carefully move it until the dog clutch is only slightly engaged. When engaged but very slightly, there is no noise too.

So, my last conclusion is that maybe the clutch fitting is so tight that slightly forces the alignment of the sliding gear in a way that makes noise. This could explain too a couple of things:

- The (maybe) original peening over the clutch, that maybe tells us that the clutch fitting is a sensible point in this gear train.

- The fact that Schaublin sells together the main shaft and the sliding gear as a single spare. This seems to suggest that this assembly is best replaced together.

Check the sliding gear

The sliding gear (SG) seems to be in the centre of the noise issues. Thus, I decided to spend some time checking the geometry of this part. That’s not an easy task given my set of measuring tools but let’s try it.

Teeth contact pattern

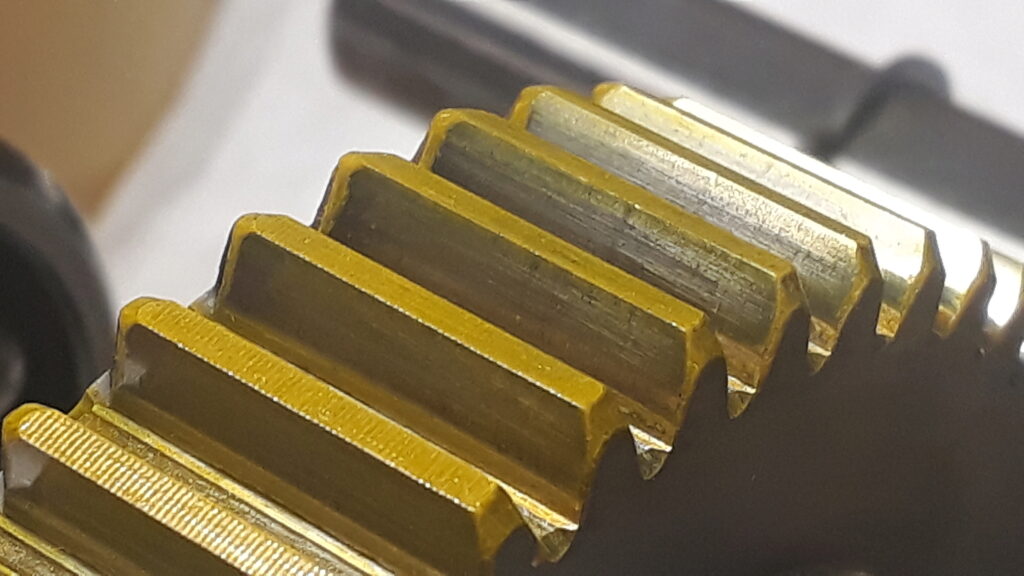

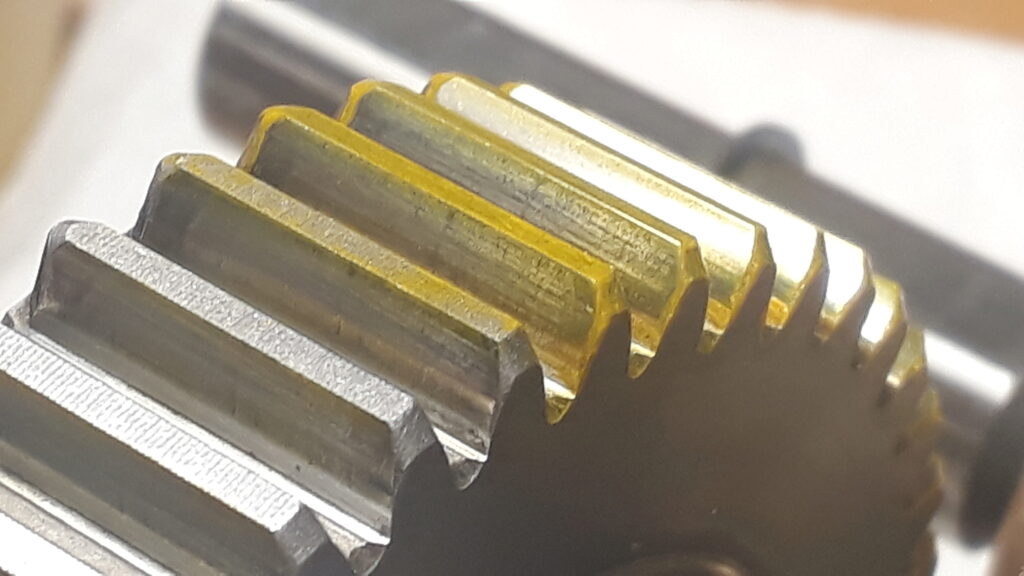

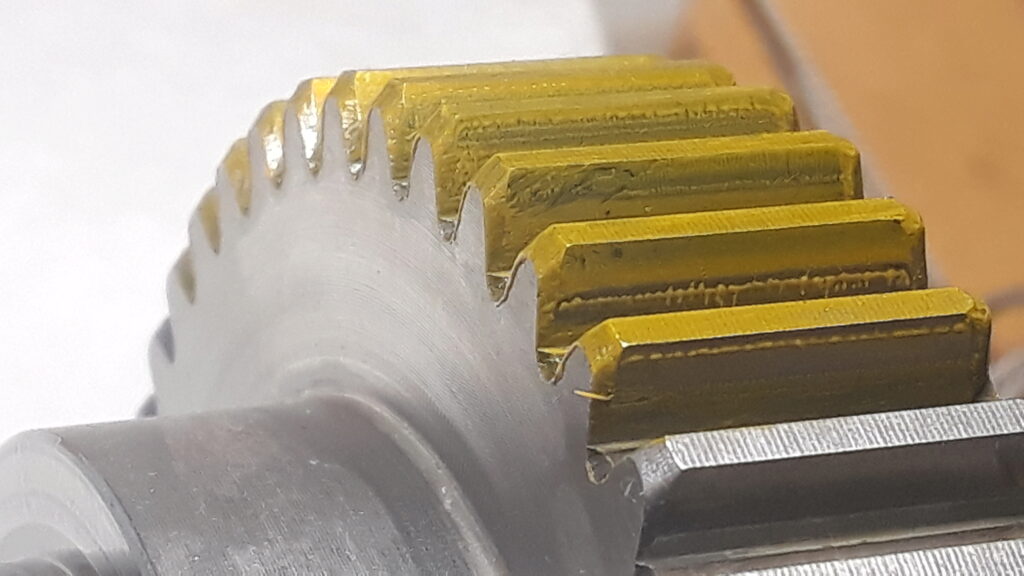

First, the teeth where painted and then the gearbox but the idle shaft S3 mounted again. After running during a short time, the printed contact on the gear teeth can be seen. The next pictures show it. I noticed no flaws in the contact pattern: well distributed along all the tooth face without singular contact points.

The gear was running in a single direction. Thus, the non-contact face of the teeth should show no contact points. From the following picture it seems that there is no contact as expected. However, a small line trace can be seen which I guess it is the result of an impact. This would confirm that the noise can be classified as «rattle».

In the previous pictures it is clear the condition of the teeth. Is seems that there is not significant wear. The top land of the teeth is in pristine state with no dents or burrs induced by wear.

Gear eccentricity

The next test has been to check the eccentricity of the gear with respect to the bearing. Because I wanted to measure over the tooth surface instead of measuring over the top land, I ended using the precision blocks tooling with a suitable diameter pin. The pictures below show the tooling and the measuring way. The result was a very good eccentricity with an approximate deviation under 0,01mm.

Dog clutch eccentricity

I also tested the eccentricity of the female spline of the dog clutch. Remember that it shows marks of have being hammered. I used an approach not unlike the last one. However, in this case I measured the play for every diameter using an indicator. I discovered some eccentricity that at most amounts 0,04mm. The next pictures illustrate this procedure.

It is not clear to me how this eccentricity could influence the noise generation. It must be some clearance between the female and the male part of the clutch and this clearance could compensate this eccentricity.

Sliding gear play over the shaft

I practised also some tests of the sliding SG gear on the shaft MS. The goal is to observe if when I connect the clutch there is any misalignment of the gear. The next video shows how this is done. With the indicator attached to the sliding gear and measuring over the shaft, I moved the sliding gear in a rocketing movement while measure the play. I have done this in a free position and also with the clutch connected. You should take into account that there is an amplification of the play measured because of the position of the indicator. Some results are: (1) the play when free is about 20-30µm, which is right enough given the tolerances that Schaublin exhibit in the drawings; (2) the play is reduced when the clutch is connected but still there is a play of about 10µm. This do not depends on the relative position of the clutch.

Bearing diameter

Just to have all the data, I checked again the diameter of the bearing in three distinct depths. The results go from 30.005 mm to 30.010mm, which is on the low range of it’s tolerance class. The pictures below show this.

Reading… and trying to understand

Being myself in a cul-de-sac, I tryed to break it by reading on gears extensively. In parallel, together with my colleague Jordi Bonet, we started to analyse the sound produced by the gears applying signal processing techniques.

The bibliography search conduced me to a paper of Rigaud and Perret-Liauded entitled «Investigation of gear rattle noise including visualization of vibro-impact regimes» in the Journal of Sound and Vibrations (doi:10.1016/jsv.2019.115026). This paper allowed me a deeper understanding of the physical/mechanical nature of the rattle in gears and pointed me to other papers also interesting.

An important progress was to confirm that the main cause of rattle is the velocity fluctuation of the drive system. The conditions that can influence on rattle noise are (a) the inertia of output gear; (b) the drag torque; (c) the backlash; and (d) the lubrication.

In the SV13, the conditions (a), (b); and (d) are unchanged from the initial design of the machine. Backlash, however, could have been be modified at least two reasons:

- Teeth are worn by some reason

- Center to center distance between gears have changed (for instance because bearings are worn out or shafts bent).

Given that option (2) does not apply, only option (1) could be the cause. However, as explained in the last section, the inspection of the gear do not shows evidences of being worn. Indeed, the contact patterns exhibit a good condition. Then, some wear must exist as usual, but it seems not to be enough to be considered. It would be interesting to have the annotated original drawing of the gear to try to compare measures and get an analytical measure of wear if possible. Schaublin service, has declined to make public this info considering it’s a part still «in production».

All this reasoning conduced me to think in a single important cause: the velocity fluctuation of the drive system, that is the Reeves variable speed driver of the machine.

Finally, the belts

Having concluded that the cause would be the variable speed belt driver, I checked again the pulleys alignment and its shape. I saw no fault. Following, I tried to modify the belts tension. By some intuition I first increased the tension in small steps with no success. After that, I proceed by decreasing the tension until reached a point where the rattle dissapeared. Alehop!! Incredible…

The next video, shows clearly the rattling noise before tweaking the belt tension. Note that only the two involved gears are in the gearbox and there is no oil. In the next video, the belt tension was modified. The rattle disappeared and only in the very low range of speed can be heared (by the end of the video).

It seems that the optimum belt tension is critical to assure a smooth circular motion.

To wrap up

This has been a very odd adventure with a happy end. All began with the unexpected noise during the first run of the machine. The cause was discovered soon: the heavily worn out bronze bearing. I had high hopes on the replacement of the bearing. The result, however, become upsetting: a heavy noise remained (that some time after I discovered it should be described as rattle). This pushed myself to a kind of crazy race to understand what was the cause: measuring, mounting, unmouting, reading,… At the end, the cause was really simple: too much tension on the belts. Many weeks, and many work to end in a so easy thing. A big experience after all.