The work on the power hacksaw is slowly advancing. The saw was completely disassembled and cleaned. It was really dirty, full of chips and old grease. Just to show the state, look at the cutting fluid tank absolutely full of chips. The last owner shouldn’t be very proud of it…

After disassembling the general state observed is good enough for a maybe 50 or 60 years old saw. Most of sliding parts are well fitted.

The Leinen lathe comes with a two speed 1:1/1:8 reduction gearbox that can be operated while the machine is running. It works by using a multiple disks oil bath clutch.

We disassembled the gearbox to check its condition. The reduction has a very thick deposit of oil after years without maintenance. Disks are in good condition and shaft seals are a bit worn.

The following image shows the reduction set of parts after unassembling it.

After being adjusted, the compound rest shows two issues:

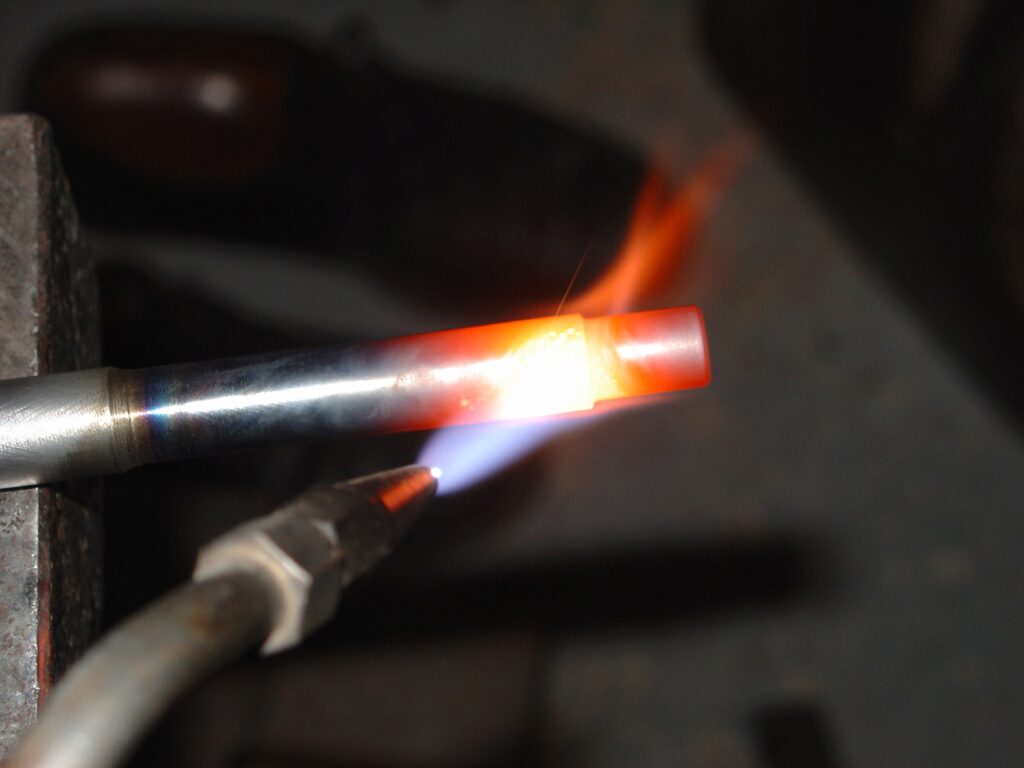

The motion screw exhibits a play that cannot be decreased. Provably the adjustable nut is severely worn. The crank has a fixed friction point when turning. No hints about the causes. The compound rest has been dismantled and thoughtfully cleaned. First it was necessary to make a special socket wrench for the adjusting nuts of the compound gib. Next picture shows the wrench.

The contractor’s cabinet saw with sliding table S250 —made in Italy— was bought to the woodworking tools trader Miquel Martínez almost as scrap. The seller was really fair and honest and never tryed to hide the real problems of the machine. However, I was heavily interested in this given its dimensions and overall buildin quality.

Moving the machine at home was done by the seller itself. This machine is mainly built as a sturdy steel plate cabinet that supports a cast iron top where the 250mm saw tilting mechanisms are attached.