The apron Following with the overhauling of the Leinen LZ4SB now the star is the apron. The Leinen apron is double walled and all the mechanisms run in an oil bath. It has an clever mechanism to stop the transversal and the longitudinal advances when there is too much torque. This allows to work with adjustable stops during automatic turning or facing operations.

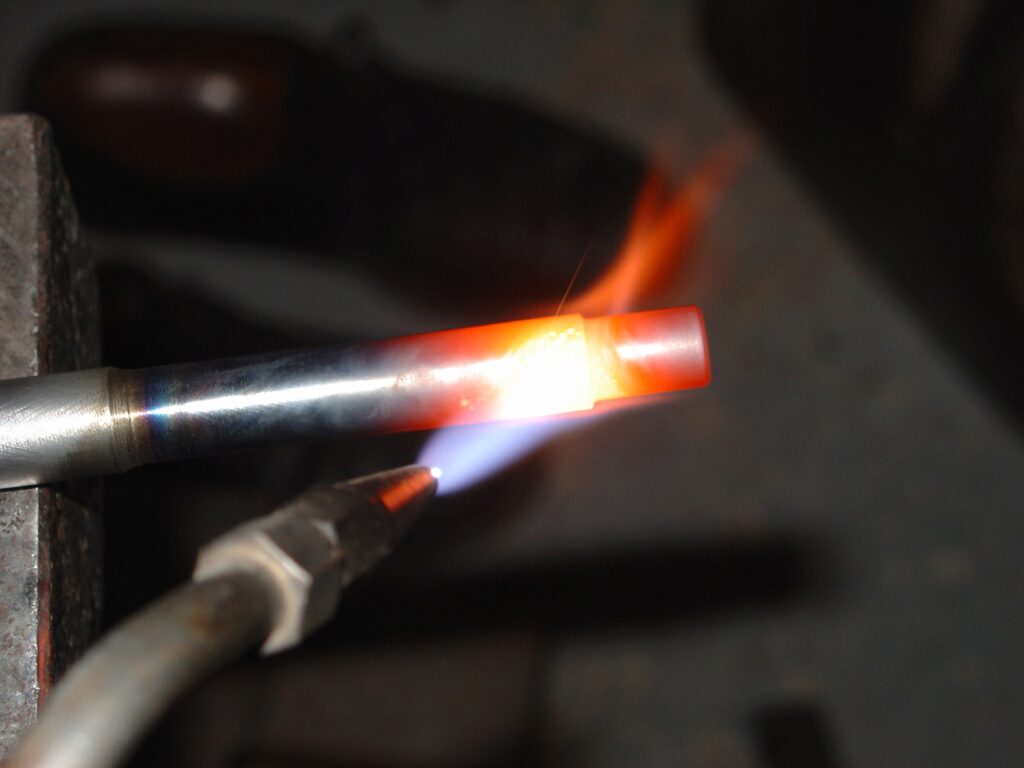

Power transmission between the feed bar and the apron is done through a worm drive placed inside the apron case.

An important task during the Leinen lathe refurbishing is to recover it’s original aesthetics. This a time consuming process if you want a quality result. These are the main tasks:

- Clean and remove rust of surfaces

- Polish the surfaces

- Prepare the surfaces to be painted

- Paint

Let’s start by restoring the tailstock, which seems to be in pretty good condition. Tailstock is unusual since it is designed in such a way that the barrel remains fully supported despite its position. It’s a typical construction of some precision machines. The tailstock is fixed to the bed using a lever that acts on a cam lock. The spindle is locked by classic crescents. The fit of the barrel is very good, especially in the first part of the displacement.

The contractor’s cabinet saw with sliding table S250 —made in Italy— was bought to the woodworking tools trader Miquel Martínez almost as scrap. The seller was really fair and honest and never tryed to hide the real problems of the machine. However, I was heavily interested in this given its dimensions and overall buildin quality.

Moving the machine at home was done by the seller itself. This machine is mainly built as a sturdy steel plate cabinet that supports a cast iron top where the 250mm saw tilting mechanisms are attached.