The Schaubling 13 oil level sight glass should be replaced because the original one was chipped off after pulling it out. Which materials and how to mark it?

The Schaubling 13 oil level sight glass should be replaced because the original one was chipped off after pulling it out. Which materials and how to mark it?

The SV13 is clean and painted. All the mechanical issues have benn solved. Now it’s time to reassemble it.

Here I face to recover the original aspect of the Schaublin 13. I will try to preserve original colors and distributions and, to some extent, the original coating where possible.

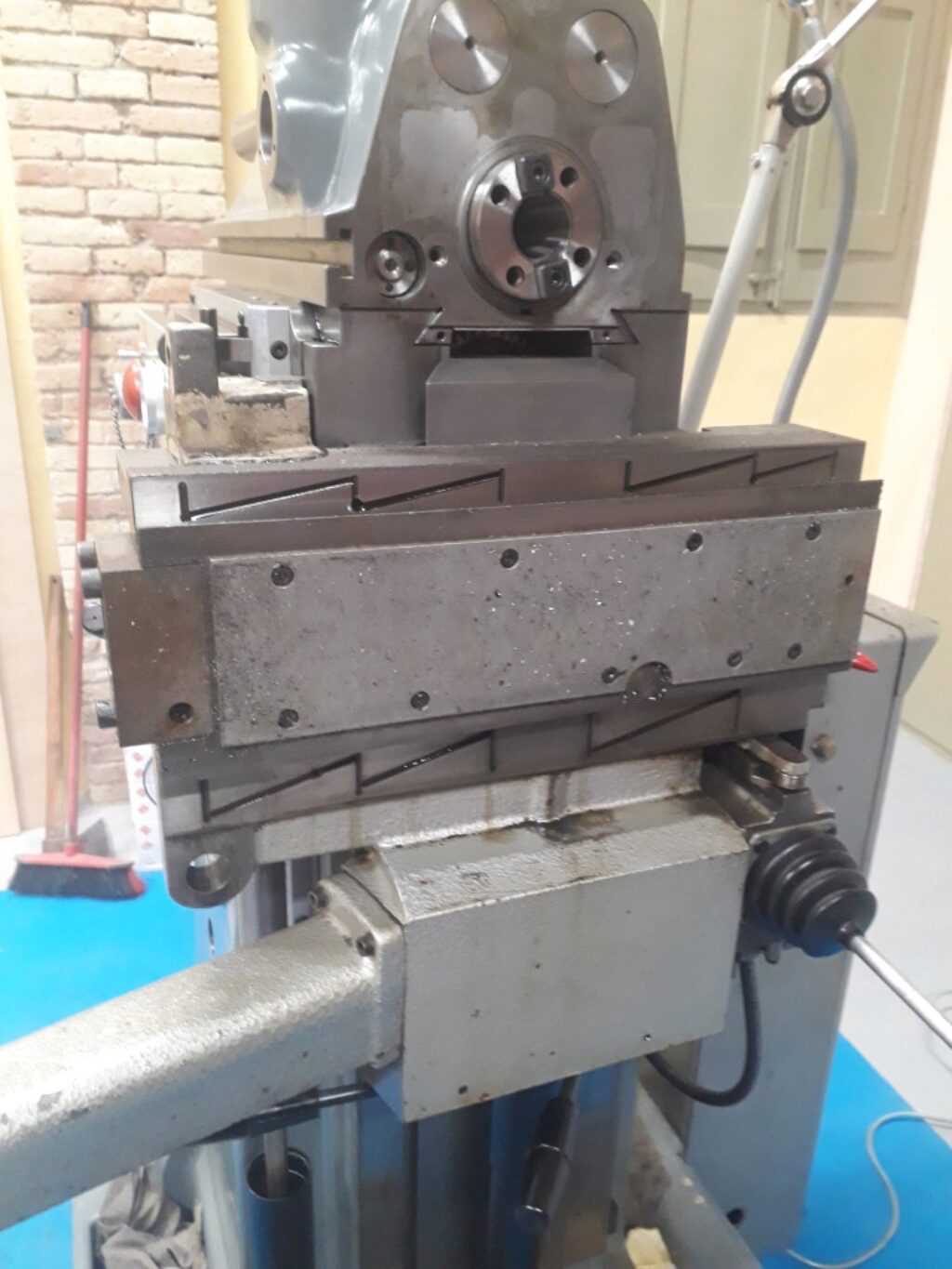

This post explains the disassembly of the milling machine knee together with the mechanisms related to the automatic traverse feeds. This includes the assembly that drives the traverses from the main motor.

Last days, I discovered that old grinding belts are prone to break by the scarf joint. This is an annoying but solvable issue.

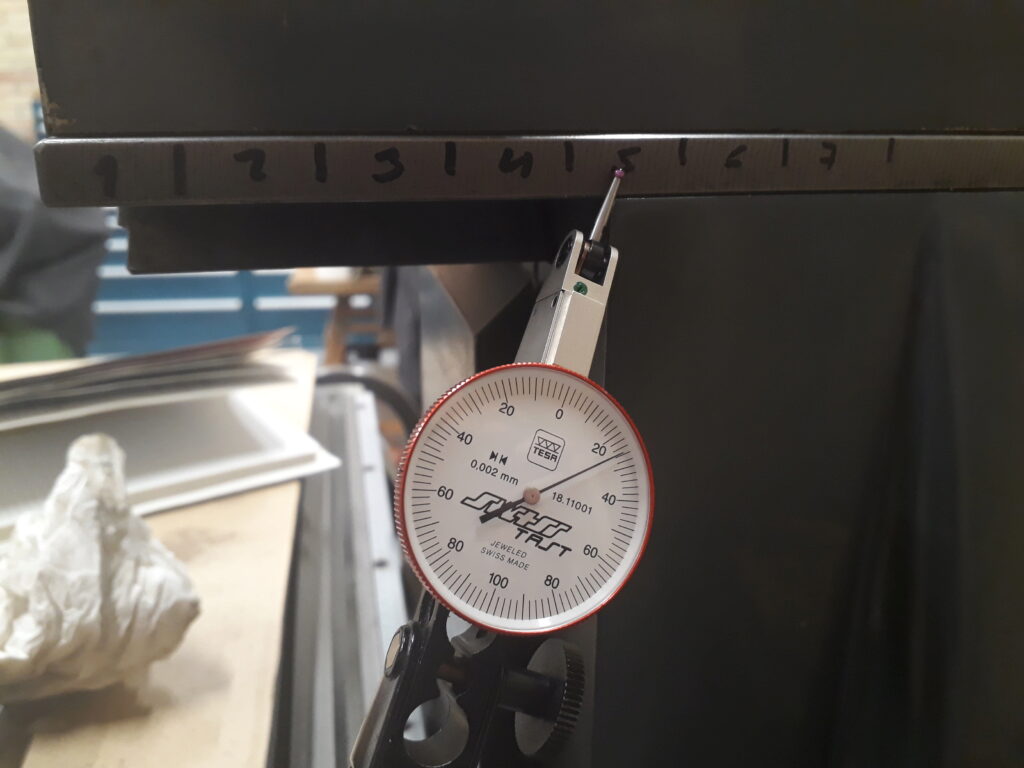

The last post discovered the Y axis ram problems. In this post I explain how the aligment problems were (partially) solved. This is the result of a long journey through geometry and aligment testing, scraping learning and lots of patience.

The first tests done when machine arrived at the workshop discovered an issue on the geometry of the ram —Y axis—. The ram has a sensible play in some positions that can be measured when moving it on the Y axis. This will be one of the most interesting problems to repair during this rebuilding.

The last summer I spent some time to design and make some cabinets to store my material under the worktable. I had no time to report about before. In this post I will show some details.