I posted the last info many moths ago. During this time I have been commissioned for a non-permanent job position that consumes part of my free time. This and some personal issues have mostly maintained me out of my hobbies. In a series of posts that will follow this one, I will try to detail some of the activities that I carried out during this time.

An interesting machine any workshop needs is a tool grinder. In the net it’s possible to find information about many home made tool grinders (or tool grinding gigs). Most of the designs have known names related to the design author. This blog entry is the result of collecting some of the designs to build a small tool grinder for the workshop. Any suggestion about a missing design will be considered ;-).

An old Waldmann WD 306 luminaire is added to the Boley Leinen lathe. The luminaire is nowadays old but it is still a very good design. Can be found at a reasonable price and, after servicing it, make a very good value for money.

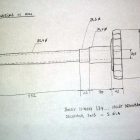

Some days ago Sam Kowalski, a happy owner of a Boley-Leinen lathe asked me for the dimensions of the collet’s drawbar. He is posting some nice pictures of his lathe restoration in the Old Wood Working Machines forum. Sam, here you have a handmade sketch of the drawbar ;-). Don’t hesitate to ask for more details if needed.

Beware that last informations about Boley Leinen collets for LZ4xx lathes tell that the threading is not M23x1 but a specific thread, say Z23x1, the profile of which is 55º instead of 60º of metric standard.

Before and after Before:

After:

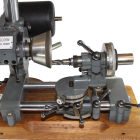

Some pictures of the lathe After more than a year of investing time in the great Boley-Leinen LZ4SB lathe, the following pictures show the result:

The Leinen LZ4SB lathe cabinet has a drawer that is usually used to store the collets set. This requires to make a wood support to organize the set. I want also to store some usual tools: some live and dead centers and the wrenches needed to operate the lathe.

I begin by cutting a couple of plywood pieces to the approximate size of the drawer. I glue them to obtain a thicker plywood support.

The Leinen LZ4SB leadscrew is supported by two bearings. One of them, the corresponding to the adjusting end, has been eroded maybe for a deficient lubrication. This need to be faced again to recover the bearing surface. We plan to do that using a boring head on the milling machine. To support the part in an orthogonal position first an adjusting stud is turned in a lathe. This will guide the bearing when clamped to the table.

The Boley Leinen collets have been a controversial issue. Sometimes difficult to find in a good condition but available time to time. There are no public Boley Leinen information about the right collets to be used. This poses some questions that owners are solving as the time goes. This post shows what collets are and features the most interesting information about them.