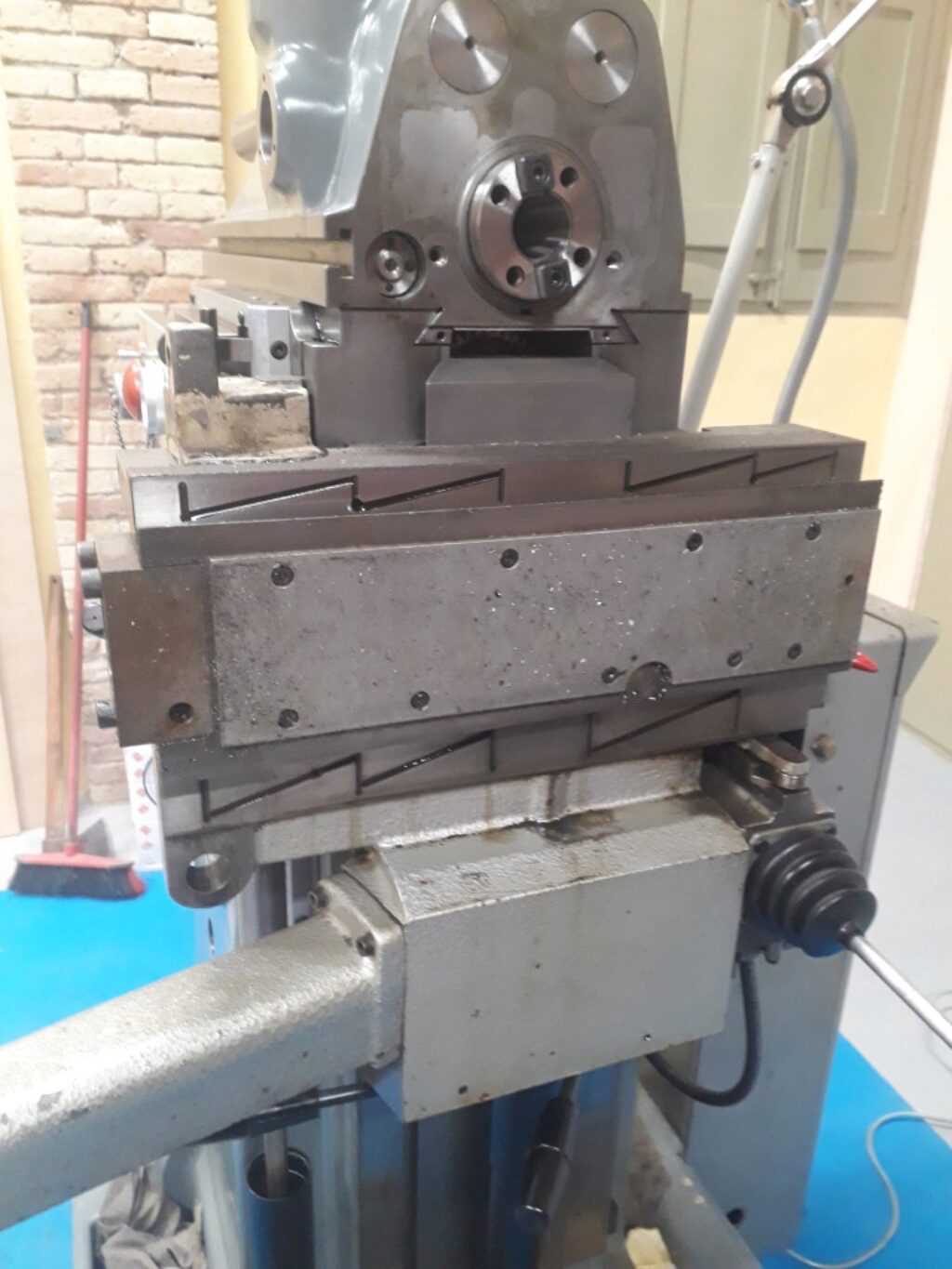

The SV13 is clean and painted. All the mechanical issues have benn solved. Now it’s time to reassemble it.

The SV13 is clean and painted. All the mechanical issues have benn solved. Now it’s time to reassemble it.

Here I face to recover the original aspect of the Schaublin 13. I will try to preserve original colors and distributions and, to some extent, the original coating where possible.

This post explains the disassembly of the milling machine knee together with the mechanisms related to the automatic traverse feeds. This includes the assembly that drives the traverses from the main motor.

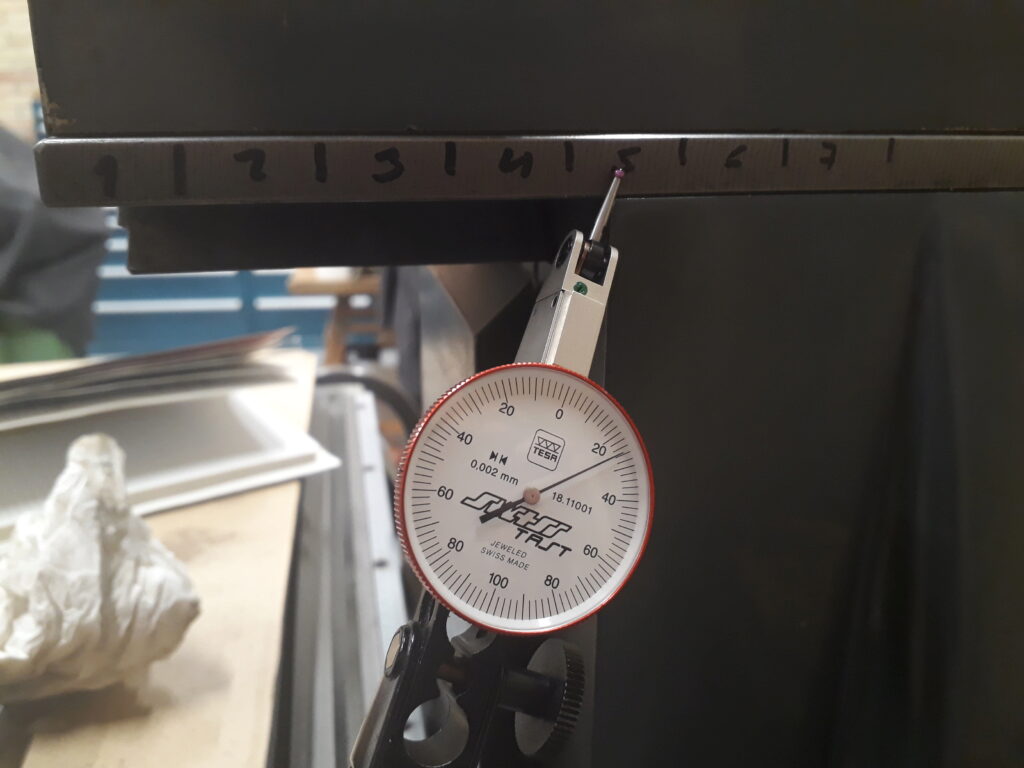

The last post discovered the Y axis ram problems. In this post I explain how the aligment problems were (partially) solved. This is the result of a long journey through geometry and aligment testing, scraping learning and lots of patience.

The first tests done when machine arrived at the workshop discovered an issue on the geometry of the ram —Y axis—. The ram has a sensible play in some positions that can be measured when moving it on the Y axis. This will be one of the most interesting problems to repair during this rebuilding.

In this post I talk about the maintenance of the Schaublin 13 table feed gearbox. It is easy to identify because it protrudes the back of the machine in an unusual way.

In this post I show the maintenance of the Schaublin 13 Reeves drive. Together with the main gearbox, it constitutes the milling machine power drive. You will see how I dismantle, clean, examine and service it.

Long time ago I bought a Schaublin 13 milling machine to Peter at Veltman Machines. This was to replace my Cincinatti Chomienne FP30. The machine remained stored for many months and finally it arrived the time to face its refurbishing.

In this post I face the service of the motors and rework the electrical conducts.