Nothing annoys more to me that a machine loosing oil and spilling it on the floor. Despite this, many machines are designed with not too much attention to this detail and lost oil mechanisms are usual. The Schaublin 13 has also some mechanisms that loose oil by design and some of them spill the oil on the floor.. ugly design I would say.

The variator displacement shaft is on of those assemblies. It displaces the variator pulley up and down while maintaining the aligment. The vertical shaft moves constrained by a couple of plain bearings that should be lubricated. Oil arrives to the shaft following a descending way: it flows from the variator handle bearing to the mitter gear, from this to a small bassin on top that oils the axial bearing, the feed screw and the vertical support shaft. After this path.. oil drips over the motor ☹

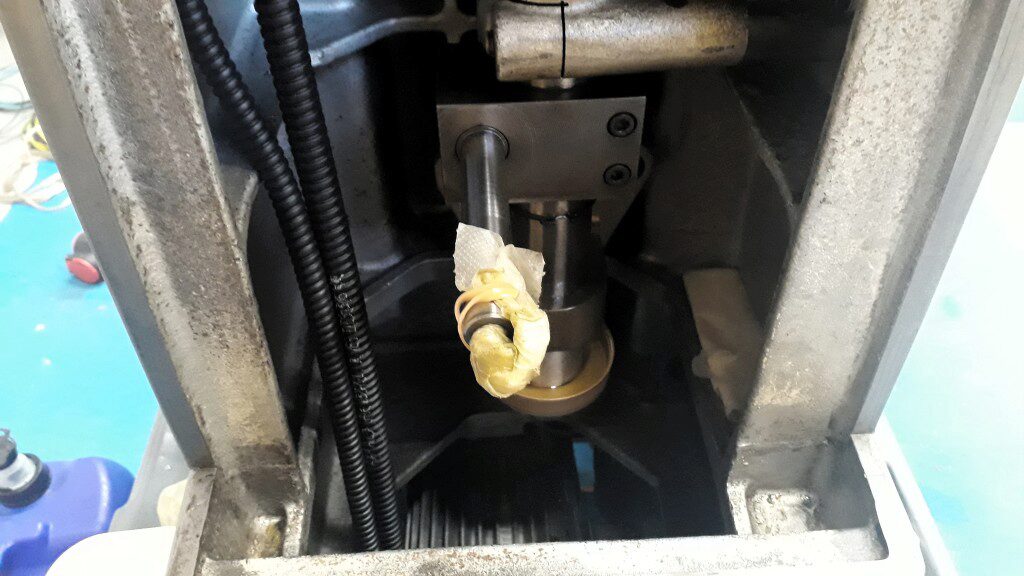

I decided to put an oil pan just in the bottom of the shaft. I made it by turning an aluminium part and adding four magnets to attach it to the shaft. The magnets also maintain a space between the shaft and the collector to allow the oil to flow from the interior of the shaft. The aluminium part ends with a plastic lid recycled from some kitchen can (not the fancier, I would admit).

It is easy to pull out to empty the lid when full and avoid oil spilling over the motor. I wish it to be an improvement.

View of the oil pan when attached to the bottom of the shaft

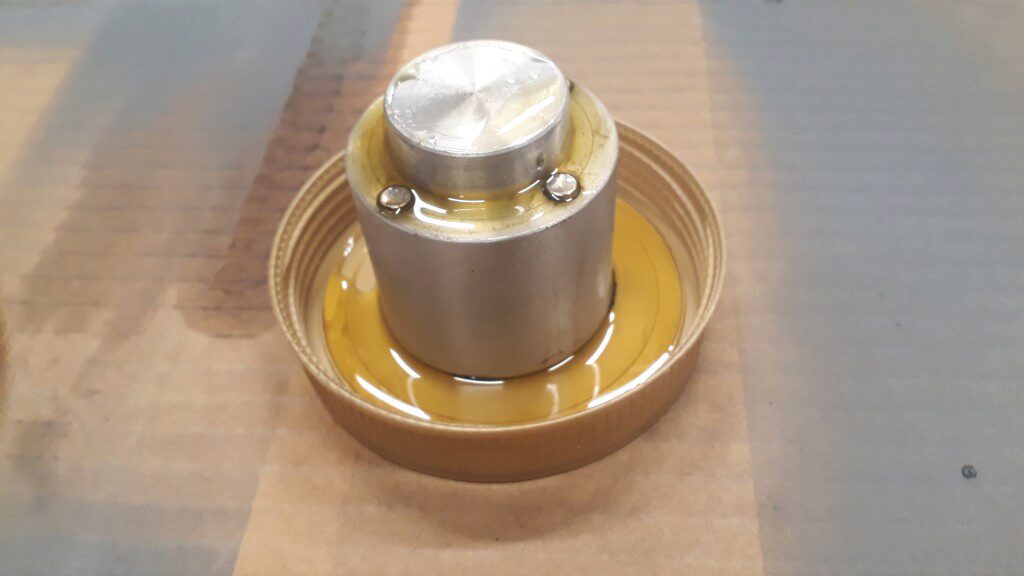

The simple oil pan. Note the recycled lid.