The SV13 is clean and painted. All the mechanical issues have benn solved. Now it’s time to reassemble it.

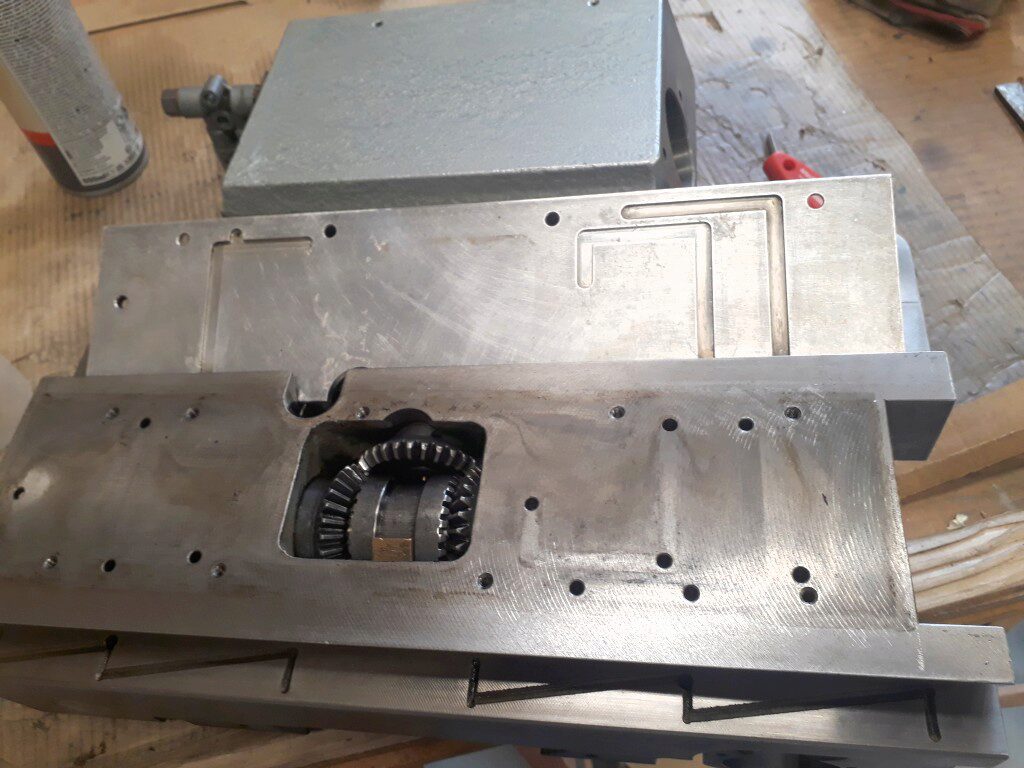

First, assemble the gearbox of the table power feed

The box should be mounted first, to let the fast feeds motor to be mounted after. This box is mounted without the gearing, that will be setup later.

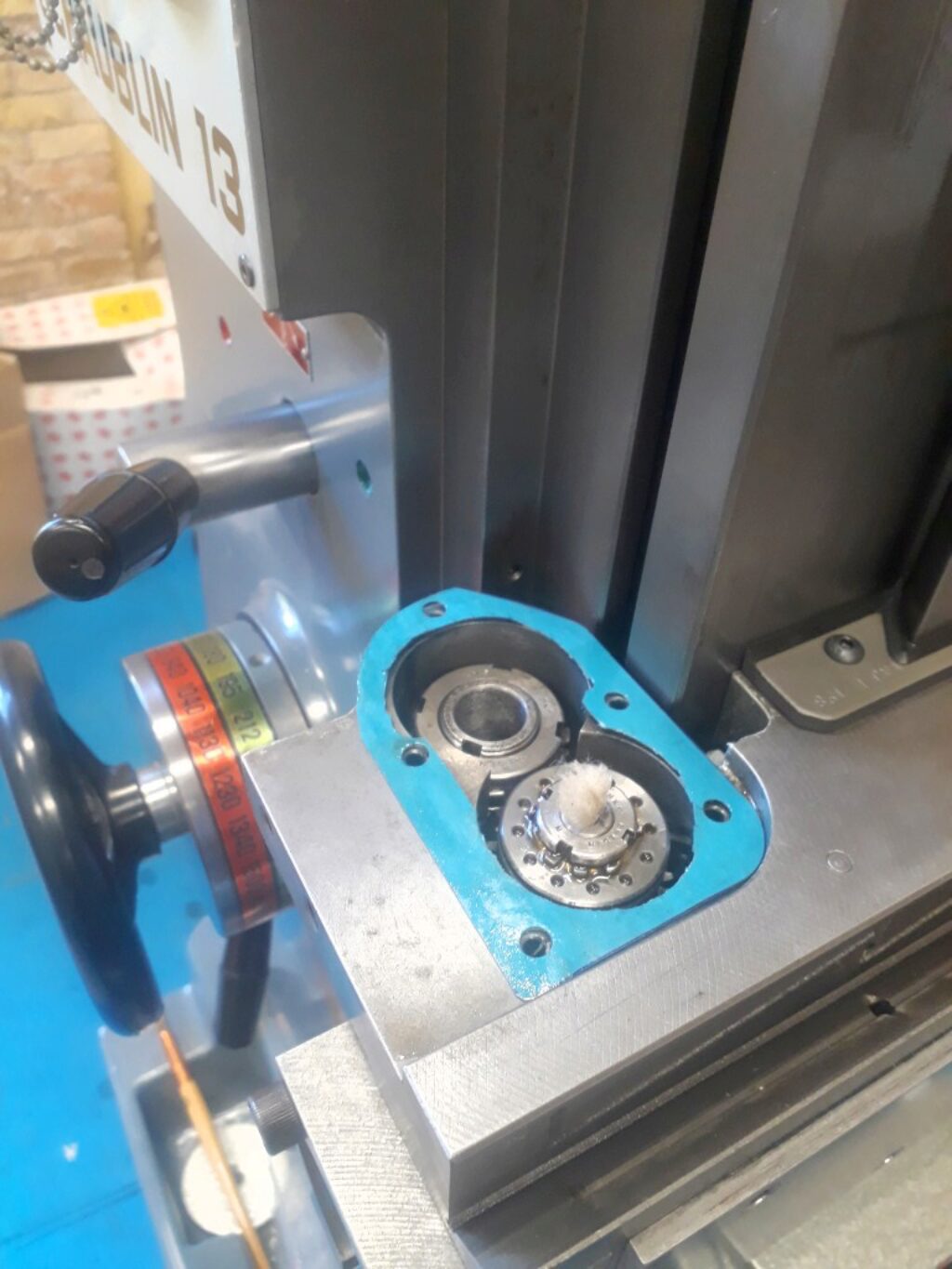

Re-assemble the motors

Next step is to set up the motors. I begin with the fast feeds motor. Previously, I decided to replace the bearings, mostly because the motor was in a very unaccessible place and, I preferred to assure I will not nedd to set apart in the future.

Then, the motor is put in place with the help of some wood plates to support it in place. The elastic joint should be in place.

After that, the power motor is put in place. Not easy to set up. It has a single position where it do not clashes with the feeds motor. Lots of patience.

Re-assemble the variator

Now, mount the variator and the speeds handle. The speeds handle includes the mechanism to rotate the drum that displays the current speed. Despite the intuition, it was very easy to mount ans syncronize with the variator position.

The lube pipes have been also cleaned. Mostly by circulating WD-40 through them. In some cases also a pipe brush was used. Pressurized air was also useful.

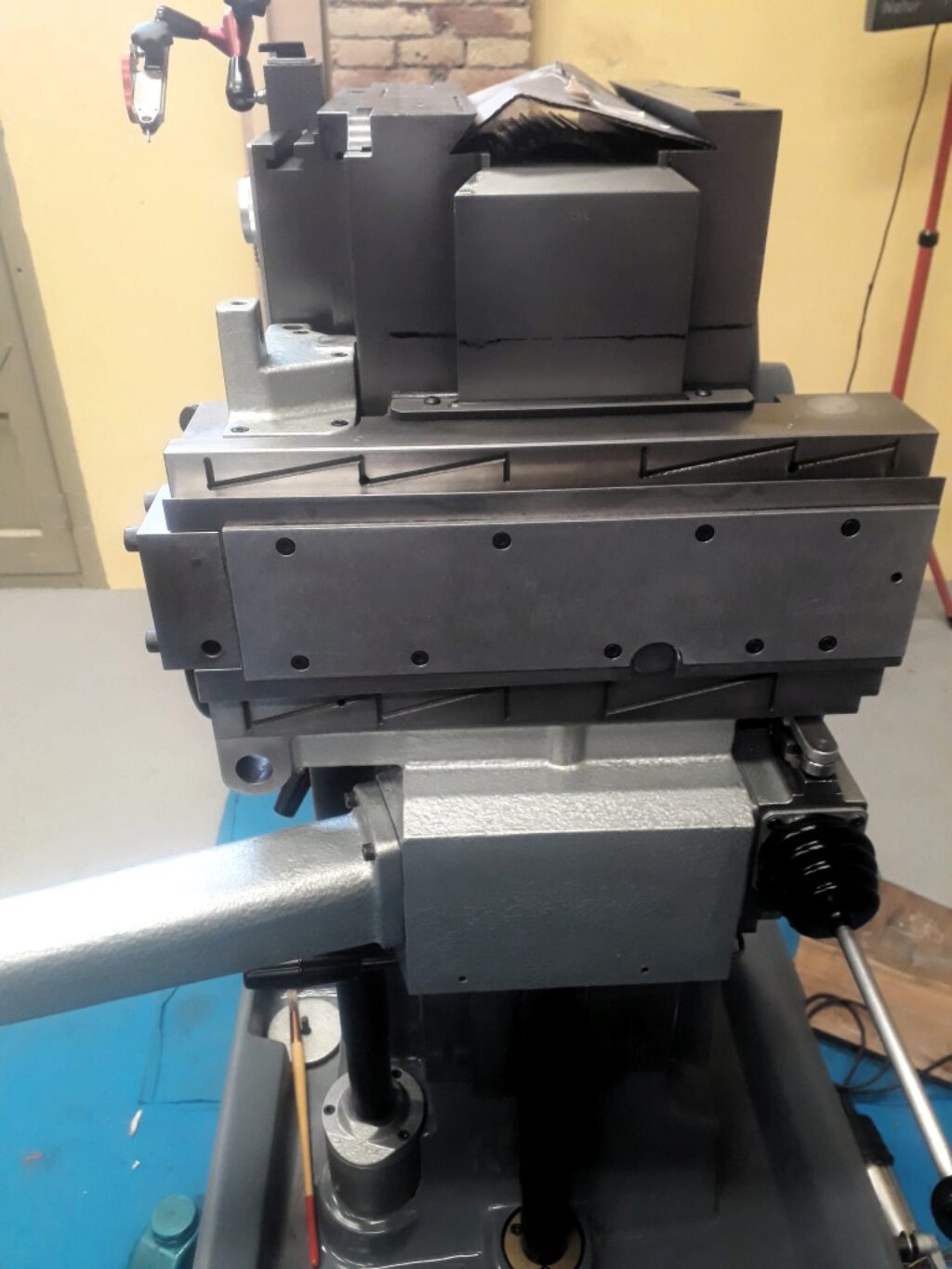

Assemble the knee

Time to assemble the knee. Make the last settings: set the centering off the horizontal clutch driver. It has just 0.1 mm of play to each side!

Put the covers of the knee:

Finally, the knee is moved to place with the hoist help.

Then, I mounted the Z feed handle assembly, after that the Z lock bar and handle and, finally the feeds lever box. Also, the cover of the feed security clutch mechanism was screwed on.

Note that I also added a dirt protection in the top of the knee. It was a missing part. The spare has been bought at Quality Tools.

Adjust the knee gib

With the help of an indicator, ajust the knee gib. The target is to diminish the rocking movement of the knee while maintain a good slide feeling. The lock lever action should induce almost no rocking too. I achieve a displacement of about 0,003 mm at most. Next video shows it.

Inthe video, first measures are taken by trying to rotate the knee using as a lever the protuding handle of the Z axis. The second measures are obtained by locking/unlocking the knee using the lock lever.